Miyuki Acryl was established in 1970 but is absolutely on trend today. Based in Adachi, Tokyo, Miyuki Acryl is a specialist in acrylic, selling its own brand of acrylic materials and products with the option of decoration using a Roland VersaUV LEF-12 UV printer.

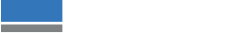

The Miyuki Acryl studio is located in a residential area of Kita-Ayase

The Miyuki Acryl studio is located in a residential area of Kita-Ayase

Its factory makes more than 6,000 different types of acrylic in transparent and solid colours, marble and lamé patterns, and even infused with real fabrics. Acrylic is currently a must-have material for products like statement jewellery, and Miyuki Acryl artisans craft each pattern to appeal to designers. The showroom displays some 700 types of acrylic sheets – sold under Miyuki Acryl's own acrylic brand called TOKYO ACRYL – like a record shop for customers to browse through and purchase.

The Miyuki Acryl showroom features acrylic sheets lined up like a record store

The Miyuki Acryl showroom features acrylic sheets lined up like a record store

Customers can browse through and purchase some 700 types of acrylic sheets in various colours and sizes

Customers can browse through and purchase some 700 types of acrylic sheets in various colours and sizes

A Roland VersaUV LEF-12 UV printer is set up in the Miyuki Acryl studio

A Roland VersaUV LEF-12 UV printer is set up in the Miyuki Acryl studio

"We wanted the general public to discover the true beauty of acrylic, so we began selling acrylic sheets that we designed ourselves, and started taking part in more events throughout Japan and overseas like Taiwan," explains Miyuki Acryl's Vice President Masaya Ono. "Now we even have international customers dropping by after finding information on the internet about the acrylic we manufacture here."

Workshops provide hands-on experience working with acrylic

The factory space also hosts workshops, enabling customers to work with acrylic and create unique products themselves, and has a gallery of vintage Miyuki Acryl pieces to inspire them. Recently, a team from Roland attended a workshop with overseas sales partners from the Middle East, Africa and Taiwan to explore how this versatile material can be used with Roland technology to produce stunning items.

Miyuki Acryl staff welcomed overseas sales partners in charge of Roland DG product sales in the Middle East, Africa and Taiwan regions

Miyuki Acryl staff welcomed overseas sales partners in charge of Roland DG product sales in the Middle East, Africa and Taiwan regions

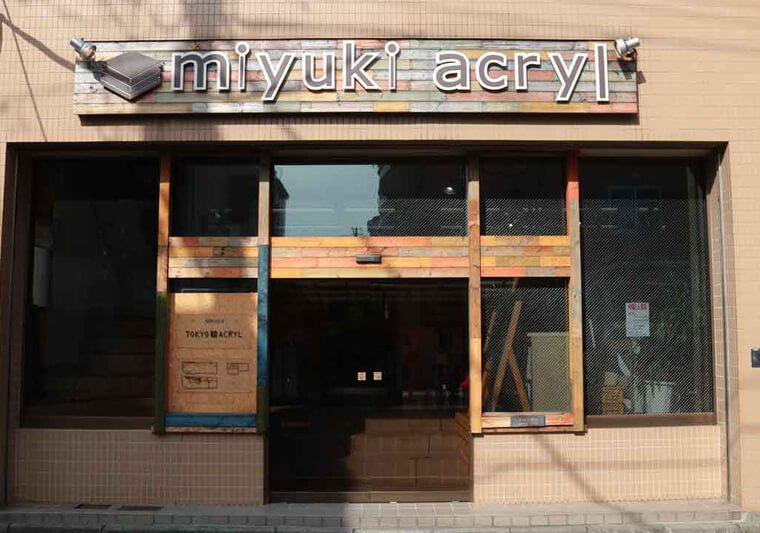

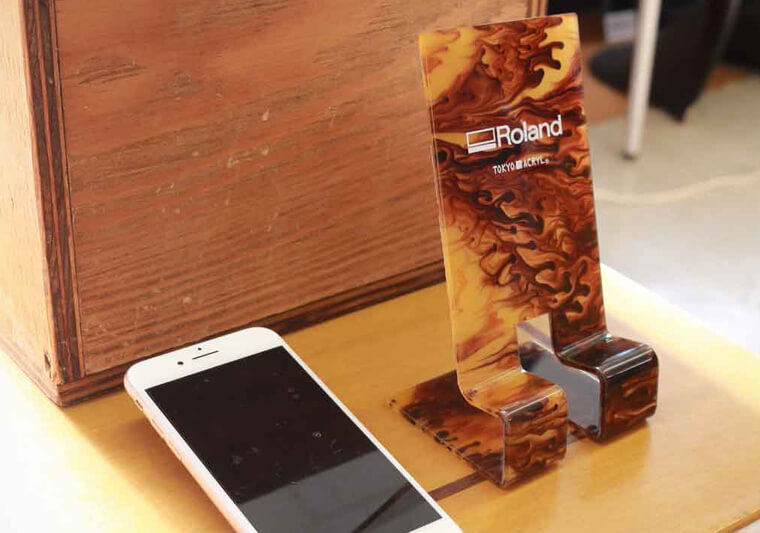

Getting hands-on with acrylic, the visitors learnt two different skills: bending and dyeing. Acrylic is easy to bend into shape at relatively low temperatures, so participants got involved by making their own smartphone stand using their choice of coloured or patterned acrylic sheets from a selection. These had been laser-cut into shape and printed with the Roland VersaUV LEF-12 UV printer in advance, allowing the participants to focus on heating the acrylic and bending it into the perfect stand shape.

Bending acrylic using an acrylic bender

Bending acrylic using an acrylic bender

Smartphone stand made after selecting acrylic sheet with the desired colour or pattern

Smartphone stand made after selecting acrylic sheet with the desired colour or pattern

Heating up acrylic by holding it close to a heater, and then bending it into shape to form a stand

Heating up acrylic by holding it close to a heater, and then bending it into shape to form a stand

Participants focused intently during their first time working with acrylic

Participants focused intently during their first time working with acrylic

Taking a hands-on, practical approach to learning about acrylic fabrication

Taking a hands-on, practical approach to learning about acrylic fabrication

The dyeing workshop explored acrylic's fantastic ability to take on colour, much like fabric or paper, thanks to its composition of around six cent water by weight. Students experimented by dipping transparent acrylic keychains, engraved with a laser cutter in advance, into a pot of dissolved resin dye to achieve the right intensity of colour – similar to cooking fondue or Japanese shabu-shabu hotpot.

Transparent key chains can be dyed with stunning results

Transparent key chains can be dyed with stunning results

Resin dye is dissolved in water and heated in a pot before dipping acrylic pieces into the mixture similar to fondue or shabu-shabu

Resin dye is dissolved in water and heated in a pot before dipping acrylic pieces into the mixture similar to fondue or shabu-shabu

Once items reach the desired colour intensity, they are removed and rinsed to complete the dyeing process

Once items reach the desired colour intensity, they are removed and rinsed to complete the dyeing process

Participants expressed their amazement when dyeing their acrylic pieces in pots

Participants expressed their amazement when dyeing their acrylic pieces in pots

What does the future hold for Miyuki Acryl?

We asked Vice President Masaya Ono about some of the initiatives being taken by Miyuki Acryl.

Vice President of Miyuki Acryl, Masaya Ono

Vice President of Miyuki Acryl, Masaya Ono

"These days there are many facilities like shared factories where anyone can get involved in fabrication, and acrylic is increasing in popularity because it is a familiar material that is easy to work with using digital tools like UV printers and laser cutters. We are also seeing more people interested in the acrylic materials that we have developed over the years for customers to make their own products," comments Masaya Ono.

He adds: "By applying advanced fabrication techniques like 3D bending and dyeing, people can make items with unmatched originality. As professionals in the acrylic industry, we want even more people to discover how acrylic can be used and new ways to enjoy the beauty the material offers."

Miyuki Acryl also organises events at businesses and spaces like Makers' Base – another Roland VersaUV LEF user.

The Roland team and their international guests were able to take home their smartphone stands and keychains – unique items demonstrating the stunning versatility of printing on acrylic.

Would you like to discover more about printing directly to acrylic using Roland UV printers? Contact us to find out more, arrange a demonstration or to request a sample.

If you haven’t requested a copy of our free UV print guide, download your copy today, you’ll be amazed at the multitude of materials you can print directly too in addition to acrylic.

Request your FREE UV print guide

You can create an amazing business personalising journals, notebooks, diaries and all sorts of stationery items using Roland UV printers. Download our FREE UV direct printing guide today and discover what it could do for your business or next event.