Costaest, creating new trends in mask production

Costaest | Italy

The current situation has led many companies to seek new business opportunities to survive, this is the case of the Italian company Costaest, a modern design company that produce signs, promotional items and backlit panels handmade that has completely changed its production during the last two months.

Developing the idea

During the first days of quarantine, Vaccaro Fabio, the founder of this business, detected a masks shortage throughout Italy. In this context and in order to meet all the safety measures, the founder of Costaest took into consideration the possibility of making his own mask model taking advantage of the items he already had in the studio.

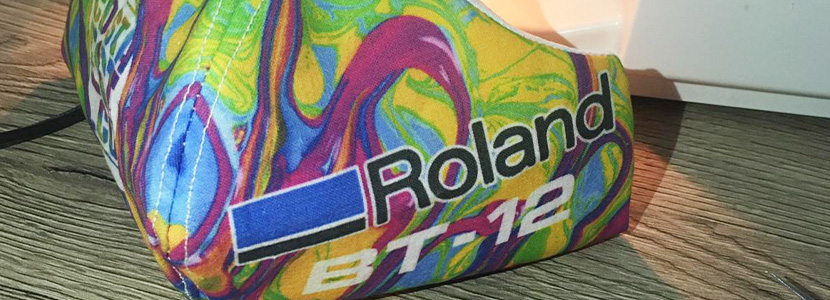

For the first prototype he used a cotton T-shirt and a piece of fabric. This first prototype was not personalized, however, later he realized that thanks to his new Roland VersaSTUDIO BT-12 printer, which the company acquired just before the confinement, and his design knowledge, he could generate a new opportunity for his business with masks customization.

Vaccaro explains, "I realized that the masks, which had been an underappreciated element until now, could become a fashionable item”.

Starting production

With Roland's BT-12 direct-to-garment printer, Costaest began customizing cotton masks with unique designs. At the time, the company acquired this desktop equipment for customizing cotton T-shirts with exclusive designs, but due to its versatility and compact desktop size, they could also use it for printing masks in a few minutes.

Currently, Costaest personalizes around twenty masks per day and combines this with the production of other items created with Roland's TrueVIS VG2-640 large format printer/cutter. The company is currently negotiating with seamstresses to increase production to around one hundred units per day.

A focus on fashion

The masks, made with 100% cotton and customized with the BT-12, have become a fashion accessory. As Vaccaro Fabio explains, "We want to ensure maximum quality over and above production volume. We are committed to creating an excellent handmade product under the 'Made in Italy' label".

The masks are available for sale through their social networks and will also be on their new website.

Costaest has managed to take advantage of their designing talent and the latest direct printing technology to adapt successfully to this new situation.

It is the responsibility of the producer of the printed facial masks to certify them in accordance with local regulations as well as the level of protection offered by the masks.

The producer must set up the washing and sterilization process. These processes can fade the image printed/sublimated. Roland DG will not be responsible for the fading of images, nor for the production and certification processes of the face masks.

For health reasons and to avoid any possible allergic reaction do not allow the printed side of the mask direct contact with the skin and follow the recommendations of your country's health institutions.