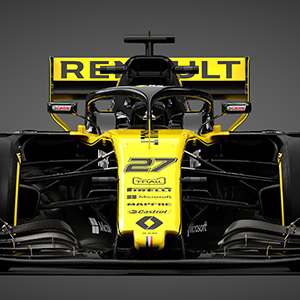

Renault F1® Team's Paint and Graphics department relies on Roland TrueVIS VG2 print and cut technology to deliver colour-accurate graphics for its racing cars and more.

Renault F1® Team has an established heritage in Formula One, a sport that reaches global audiences of more than 400 million viewers. The pressure is on to set the pace both as a business and on the track.

For many years, Renault F1® Team's Paint and Graphics department has relied on Roland TrueVIS eco-solvent printer/cutter technology to deliver durable stickers for their racing cars, displays for hospitality areas, support vehicles and more. Recently, the TrueVIS VG2 printer/cutter was installed at its Technical Centre in Oxfordshire, UK where it is pushing the quality and speed of delivery even further.

Among its more than 40 improvements, Head of Paint and Graphics Joe McNamara has praised the VG2's extended colour gamut.

#RolandHero

"The VG2's new orange swatch really makes our life easy when it comes to matching colours exactly for our corporate sponsors – and on everything we take to races with us. Every Roland machine we use is hugely reliable. We don't have downtime here. It's not an option."

"The new orange swatch has about a hundred colours in there – yellows and oranges," he says. "It really makes our life easy when it comes to matching colours exactly for our corporate sponsors and for our own branding on cars, garages, hospitality areas and other structures we deploy at races."

It's crucial that these colours are accurate and replicable across every race event, across the whole season, as stickers are easily damaged on the track and must be replaced immediately with identical graphics.

"The team always carries 30 versions of every sticker so they can be replaced whenever needed. This amounts to around 1,400 stickers for every race," says Joe. "Eighty per cent of the stickers are sponsor-related so they have to be replaced with absolute precision."

The Roland technology must also be fast enough to meet the incredibly time-sensitive demands placed on Joe and his team. The VG2's improved drying times help to achieve this.

"I know now we can actually print stuff, laminate it and, if we need to, we can ship it to Australia on the same day that we actually print it," says Joe. However, if necessary Joe could contact a local PSP on the other side of the world with a TrueVIS VG2 and know it could print identical graphics to those coming out of the machine in the UK, giving Renault F1® Team even greater reassurance.

In addition to the TrueVIS VG2, the Renault F1® Team Paint and Graphics team uses a Roland CAMM-1 GR-640 vinyl cutter and four Roland MDX-540 milling machines to manufacture foam cores for some car parts.

"Every Roland machine we use is hugely reliable," says Joe – noting an essential attribute for anyone working at the kind of pace experienced by Renault F1® Team.

Joe adds: "We don't have downtime here. It's not an option."

Joe, how do you rate Roland?

Joe's fun facts

-

How would you describe yourself in three words?

Optimistic, creative, resilient.

-

What's the best advice you've ever received?

It was from my dad, “Just believe in yourself, never give up, you can do anything you want to.”

-

What's your favourite social media platform?

Twitter.

-

In your free time you enjoy…

Reading, travel, track days in fast cars.

-

What don't people know about you?

I've appeared on a well-known TV show. My real first name is actually John. My wife and I have fostered over 50 rescue dogs through our home, and rescued and rehomed over 200.

Connect with Renault F1® Team

#RolandHero