UV Printing and Personalisation Changes the Game for The Sign Shed

The Sign Shed | UK

Rob Haywood, director of UK-based sign company, The Sign Shed, is dedicated to giving his customers what they want. Since it was founded in 2014, The Sign Shed has quickly evolved from a small, family-run signage provider to a national online retailer.

According to Rob, this speedy growth is thanks to his investment in the latest UV printing technology.

Speeding up Production with UV

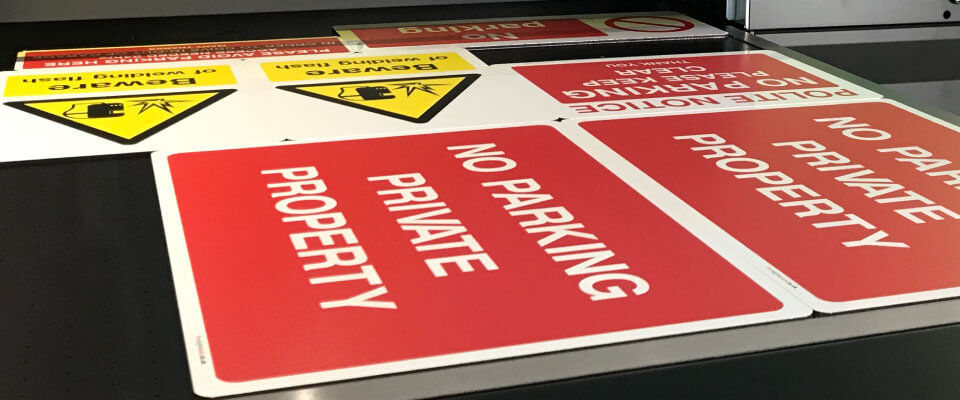

In 2018, The Sign Shed provided health and safety signage, security signs and other directional signs to clients including construction companies, public services and private property owners.

At the beginning, Rob used a Roland DG eco-solvent printer/cutter to produce his signage. Creating each sign involved several steps: printing the graphics, transferring the output to a rigid board, and laminating the result. Rob could make a quality product using this process, but he began to wonder if he could provide a faster service for his customers.

"…the addition of our new machine has reduced manufacturing times by three-quarters."

After some research, he saw a lot of potential in printing directly to boards and invested in a flatbed UV printer from Roland DG’s VersaUV S-Series range. By removing the vinyl application stages, Rob could accelerate the process and free up his printer/cutter for other jobs like producing stickers.

"Roland is a brand we can trust. Our customers expect the best and we want them to be proud of their signage; we're not cheap and cheerful, we rely on Roland to deliver top quality. Our customers also want a fast turnaround, and the addition of our new machine has reduced manufacturing times by three-quarters."

Safety signage being printed on a flatbed UV Printer

eCommerce, SEO & Online Marketing

The Sign Shop operates through an online web-shop giving Rob access to a wider customer base. Much of Rob’s success is down to a thorough understanding of online selling and marketing, using customer testimonials to highlight The Sign Shed’s superior service.

“Customer satisfaction is the cheapest form of advertising because they recommend us to other people. It is far cheaper to keep your customers happy, even if it costs you a little bit in the short term.”

When he decided to optimise his website in-house, he found it cheaper and more effective than outsourcing to an SEO agency. It was a lot of hard work and trial-and-error, but his efforts paid off and he soon began to attract a more diverse selection of customers.

“We found that it was much more cost effective to do it ourselves and we could do a better job than they could because we know our products and our market. Who better to tweak the website than the company that sells the products?”

Personalised sign in London street sign style

Personalised Signs for the Gift Market

Once The Sign Shop’s web traffic increased, Rob began to receive orders from consumers who wanted decorative, personalised signs for birthdays and anniversary gifts.

“We started off just doing safety signage, but we kept getting asked for personalised things and gift signage for people’s homes.”

Although these were slightly different from the health and safety signage he was used to making, he found that his equipment was versatile enough to let him adapt to these new customer demands.

“We started off just doing safety signage, but we kept getting asked for personalised things and gift signage for people’s homes.”

“When it comes to December, people just aren’t buying safety signs, so it’s our quietest month of the year. We were thinking what we could do to keep us busy twelve months out of the year rather than just eleven.”

Aside from filling the gap around Christmas time, Rob also found this new market to be very valuable during the pandemic when many businesses had closed their doors.

“With coronavirus, a lot of businesses were shut, but people were still having birthdays and anniversaries, so we had a plan-B.”

Bathroom door sign printed on stainless steel disk

Expanding Range with New Substrates

It wasn’t long before these additional orders brought his production to full-capacity and Rob had to find an additional solution. He returned to Roland DG and bought the VersaUV LEF2-300, a compact flatbed UV printer which easily slotted into his workflow.

“We got a new LEF2-300 last summer because the S-Series was flat-out all the time and we needed a backup.”

This let him fulfil the orders for personalised gift signs without impacting the usual demand for B2B signage, but that wasn’t the only benefit.

With the additional on-board printable primer in the LEF2-300, Rob could now print directly to more challenging substrates. Thanks to this functionality, Rob can now offer printed stainless-steel door signs as part of his growing catalogue.

Sustainable Signage as Standard

Rob understands the importance of differentiating his business from his competitors. With growing awareness for sustainability, Rob wanted to establish The Sign Shed as the environmentally conscious choice for signage.

After painstaking research, he finally found a supplier who could provide boards made from recycled plastic, rather than the typical boards used throughout the signage industry.

“I think we’re the only UK online signage retailer that offers recycled plastic material as standard across our full range of signage. Everybody is trying to do their bit for the environment at the moment, so it’s a good USP.”

“That’s the good thing about the Roland printers – they’re pretty versatile and you can print onto virtually anything, so it’s been a really easy transition for us.”

Introducing new substrates can sometimes be a challenge. This wasn’t a concern for Rob and he quickly discovered that the UV ink easily stuck to the recycled boards, giving him durable results with the same great print quality.

“We can use the Roland printer in the same way as we did with the standard plastic. That’s the good thing about the Roland printers – they’re pretty versatile and you can print onto virtually anything, so it’s been a really easy transition for us.”

Personalised bus roll-up sign

Business Expansion and Training

As The Sign Shed grows, Rob has had to hire additional staff to process the volume of orders he receives every day. His new employees don’t have any experience with the printing industry but with such a small team, everybody at The Sign Shed has to contribute wherever they are needed.

Thankfully, Rob doesn’t have to worry about a long, drawn-out training process.

“Once they get hands-on, the employees pick it up quickly. It’s also convenient that all the machines use VersaWorks, so the staff don’t have to learn a different system for each printer.”

Rob now continues to explore the personalised gift market and, led by customer requests, he is adding more and more products to The Sign Shed’s website.

Now, almost a year later, he still feels there is a lot of potential to expand his personalisation service even further. He’s confident that he has the right equipment to help him adapt and if he needs more, he knows where he will get it.