If you’re in the business of commercial print, the chances are that you’ve discovered your equipment is much more versatile than you imagined. You’ve realised that the device you bought to produce signage is perfectly capable of producing stickers, banners and even t-shirts.

It won’t be long before somebody asks you if you can also produce vehicle graphics. Before you say ‘no’, you should know that this is a highly profitable product to have in your offering. If you’ve only ventured into bumper stickers before now, then this article is for you. Here, you’ll find the key things you need to give you the confidence to start producing vehicle graphics, from cut-vinyl lettering to full or partial wraps.

Get the Right Hardware

If you want your vehicle graphics offering to be a success, you’ll need to ensure that the work you produce is of high quality. The market for vehicle graphics can be very competitive and you’ll soon notice that many companies are trying to compete on price alone.

There’s a good chance that your customers may have tried the cheaper option and discovered, to their disappointment, that the quality didn’t meet their expectations. The key to a successful business is to earn a good reputation by consistently producing high-quality work, and you can only ensure this by starting with professional-quality print devices and ink.

You can conceivably produce a good range of vehicle graphics on smaller devices, but it’s best to invest in a printer at least 54” wide to give you the biggest range possible.

Use Appropriate Media

Vehicle graphics, by their nature, are constantly exposed to a demanding environment, with constant changes in moisture levels and temperatures. The standard, everyday vinyl you use for temporary signage and adhesives probably won’t withstand these elements for very long before they start peeling, shrinking or fraying at the edges.

When it comes to vehicle graphics – especially wraps – high-quality cast vinyl should be your first choice. Unlike calendered vinyl, which tends to contract over time, cast vinyl maintains its shape and size, even when exposed to regular temperature shifts.The same applies to lamination films, which are important to increase the life of vehicle graphics – if you want to get the best results, invest in high-quality films which are fit for purpose. If you’re unsure what you need, just ask your media supplier who will be happy to help.

Invest in Additional Tools

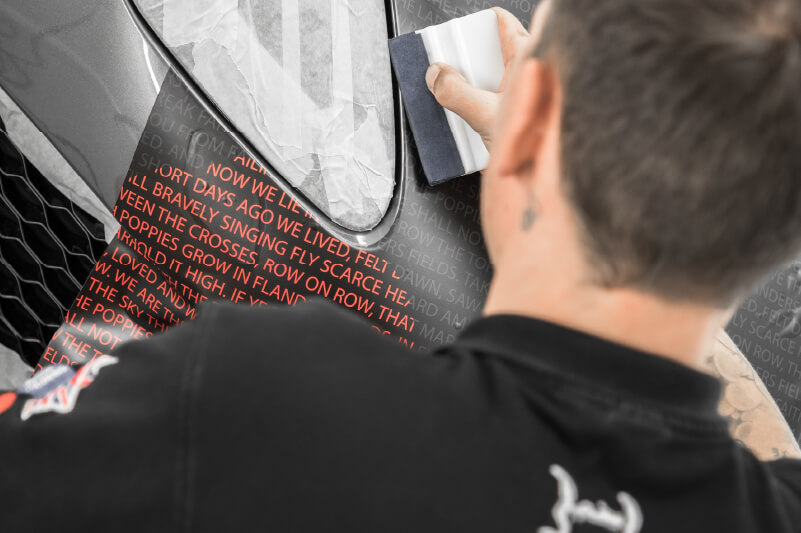

You can add lettering to the flat side panels of a van just as easily as adding it to any other flat surface, but you should be prepared to deal with tricky contours and curves. This is the basis of vehicle wrapping – the ability to apply vinyl to an irregular object cleanly and without creases.

To achieve this, you’ll need a heat gun to soften the vinyl as it’s applied, making it more pliable and amenable to varying contours. Aside from this, you can also use a selection of squeegees, magnets and knifeless tape to make the job easier. There are several other tools and gadgets available, designed for specific applications, so it’s worth researching wrapping tools – that said, don’t be tempted to buy all the toys before you’ve learned the basics of wrapping.

Practice Wrapping Skills

If you’ve been to any print trade shows, you will probably have seen vehicle wrapping demonstrations and even competitions. These seasoned professionals artfully mould the vinyl around the trickiest angles and curves, and you’d be forgiven for thinking that it looks easy. Once you get hands-on with your first wrapping job, you’ll soon learn that it’s a very fiddly and often frustrating job to attempt.

We don’t want to put you off learning to wrap, but it’s important to understand that it is an advanced skill which requires a lot of practice. Anybody can wrap a vehicle badly, but to do a professional job, you need to put the hours in to developing a professional level of skill. Start small with partial wraps before committing to a full vehicle wrap and learn from your mistakes as you go.

You can also boost your skills by attending a wrapping course – for practical skills like this, it’s often more effective to get hands-on experience from a trained professional. Search online and find any wrapping courses in your area.

Invest in Good Graphic Design Software (And Learn to Use It)

This advice goes for any print application, but it’s arguably even more important when it comes to vehicle graphics. When you’re working with such an irregular canvas, it’s even more challenging to bring your customers’ requests to life. The ability to mock the graphics up and edit elements where you need to is vital in delivering a satisfactory result.

Good-quality graphic design software lets you produce close-to-final mock-up images as well as producing the final graphics which you’ll export for use in your RIP. Spend a good amount of time familiarising yourself with the capabilities so you can more effectively produce all your vehicle graphics designs.

Get to Know Your RIP

RIP (raster image processor) platforms come in many shapes and sizes to help you take your designs from the computer screen to the printed media. Some offer very basic functionality which is great when you’re starting out in commercial print, but you can find some very powerful functionality if you spend time trying out the different options.

Particularly in the case of VersaWorks 6 - a fully functional RIP platform packaged with most Roland DG print solutions - there are tools which can significantly accelerate your production. To mention one such feature, the tiling function automatically splits larger graphics into sections, including overlap for seamless alignment. This is useful if you are producing graphics for the sides of trucks or other large vehicles.

Don’t Wrap Everything

Part of your job, as a print provider, is to educate your customers. They aren’t as familiar with print processes as you are, so when they come to you asking for a van wrap, there’s a very good chance that they don’t actually need a full wrap. Sure, full wraps are more lucrative than partial wraps, but they also take more time to produce – time which may be better spent fulfilling other orders.

In many cases, you can deliver a great result with only a partial wrap on the rear of the vehicle and a mix of cut-vinyl lettering and smaller decals across the rest of the vehicle. Not only is this quicker for you to deliver, but it’s cheaper for your customer, so everybody benefits!

Upsell

Further on the topic of educating customers, if somebody comes to you looking for vehicle wraps, the chances are high that they also need other print products, from stickers and labels to workwear. As you’re already producing similar products, and you also have your customer’s logo and artwork, it’s an easy job to add additional items to the order.

This means that you can increase your ATV and your customer no longer has to deal with a slew of other companies when they need print products – they have a single point of contact who can deliver practically anything they need. And if you can’t deliver what they need, say ‘yes’ anyway – there are countless companies who you can outsource these products to. You might not make huge profits on these items, but you didn’t send your customer to a different company who could potentially take business away from yours.

Conclusion

Vehicle graphics require skill and effort but that shouldn’t be a reason not to offer them. Your business can only grow if you explore new territory, and that will always be challenging. The rewards, however, are well worth the additional work you put in. If you have any other questions about adding vehicle graphics to your repertoire, feel free to get in touch with one of our experts and we’ll be happy to point you in the right direction.