Vermeulen & Vermeulen Reclame supports TU Delft in producing a mechanical ventilator

Vermeulen & Vermeulen Reclame | The Netherlands

Vermeulen & Vermeulen Reclame is an advertising agency based in Nieuwkuijk, the Netherlands, that’s been active in the field of signage, lettering, car wrapping and display graphics since 1996.

Entrepreneur Marcel Vermeulen could never have foreseen that in 2020 he’d be contacted by the Delft University of Technology (TU Delft) to help produce a mechanical ventilator in the fight against COVID-19. And the same could probably be said about the students at the TU Delft who contacted him in the first place. Because they too had very different plans for the year ahead, as they were scheduled to go on an internship abroad. But as the coronavirus became a reality, and concerns were growing worldwide about a possible shortage of ventilators, the professors and students at the TU Delft decided to launch a new initiative to put their cancelled internships to good use: Air for All.

Project Inspiration is one of its three main projects. Together with his students, project manager Professor Gert Smit quickly succeeded in developing a ventilator based on a 1960s British model he found at the Boerhave Museum. This so-called East Radcliff ventilator is fully mechanical – so, no electronic parts are used, making it relatively easy to build and repair.

Because it’s an open source project, the blueprints are freely accessible to everyone. The team also consciously opted for parts that are widely available everywhere in the world because the device is meant to help overcome ventilator shortages anywhere. In early May, the first prototype was sent to Guatemala, where it will be used alongside the blueprints by local production facility Talleres Hernandez, so they can learn how to manufacture the device by themselves, in their own country.

But of course, the Project Inspiration team also needed a durable, easily readable control panel for their device, and so in April, they turned to Marcel Vermeulen to help them out. They supplied their own design, which Marcel then helped them finetune, before producing the panels on his LEJ-640F.

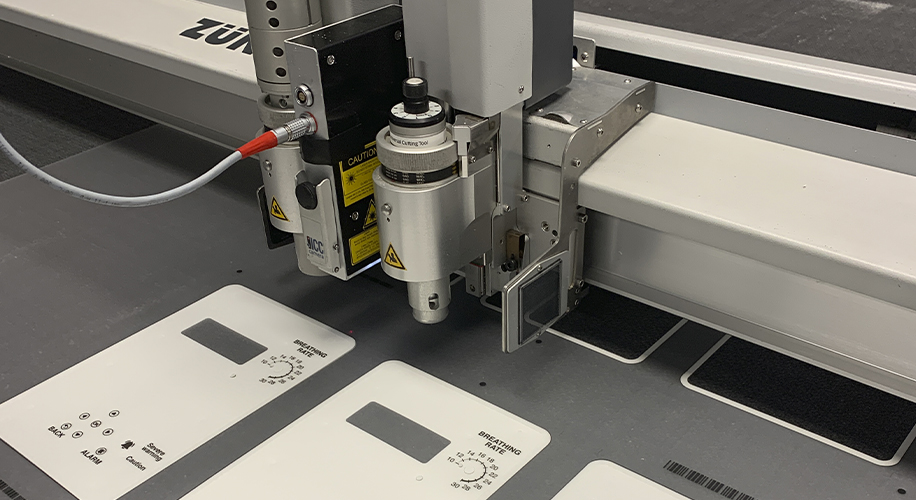

The Roland DG LEJ-640F is a large format UV-LED flatbed printer measuring 1.60 m by 3.20 m that is suitable for printing on rigid materials. Like most UV printers, it uses built-in LED lamps which will cure the inks instantly, for superior flexibility. As Marcel explains, "First we used our LEJ-640F to print the back of the panels in mirror image. That’s why we chose to work with transparent polycarbonate plates. We then cut a special double-sided 3M adhesive layer with our Zünd, which we applied to the back of each panel”.

This combination of a mirror-image printed reverse side protected by a double-sided 3M adhesive layer made extremely durable panels. “So far, we’ve printed 3 proofs for the TU Delft, but we’re expecting them to order the panels in larger quantities soon – although we don’t yet know for sure”. The sheets on which the control panels are printed are 1.4 x 1 m large and each individual panel measures 15.5 x 24 cm. "I can produce about 30 in a single run”, he says.

As to why the TU Delft decided to call in his help specifically, he can't answer with 100% certainty. But it might have something to do with the popular Dutch talk show Jinek. It’s broadcast daily and at the beginning of April, the show was recorded at Vermeulen & Vermeulen Reclame as part of the Brabant Mouth Mask Initiative (Brabant Mondmaskers Initiatief). Together with several other volunteers, Marcel has been producing face masks since the middle of March. And not just cotton ones, but masks made of real filter material.

"They are not CE-certified, but they were tested", by none other than the Delft University of Technology. The university was so impressed with the initiative that they offered to test the material themselves. "With very good results”, Marcel tells us. "This material was also used successfully during the 2009 swine flu pandemic. So even though our masks aren’t technically CE-certified, we know that they’re perfectly safe and widely usable".

These masks were distributed free of charge to various regional healthcare institutions. In the meantime, Marcel also added a wide range of new products to his webshop that can be purchased by companies and other institutions to corona-proof their buildings, such as various floor graphics, instruction panels and face shields, as well as low-cost prevention screens made of durable cardboard – an affordable and available alternative to plexiglass.

But where does this motivation come from, to produce and hand out free masks to regional health care facilities, while also creating all these new products for his webshop and producing panels for the TU Delft’s mechanical ventilators? "It soon became clear to us that the government was having difficulties providing sufficient protective materials to everyone. Plus, I knew we'd probably have less work than usual, and that I had all the necessary equipment to produce the materials right here”.

So, he thought, why not? "Above all, I wanted to help. And even though the ICUs have done a fantastic job so far and the pressure on these departments has lessened, the fear of a potential second wave remains. But this time, thanks to TU Delft, we and other countries like Guatemala, can count on these extra ventilators if we need them. If anything, times like these make it abundantly clear that people can adapt to new situations incredibly quickly and that we are perfectly capable of solving complex problems when they arise”.