ECO-UV Ink Features

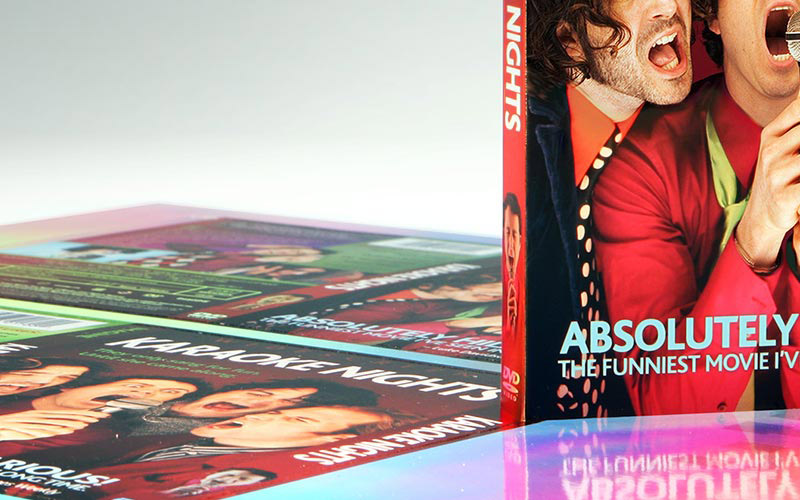

Indoor and Outdoor Applications

ECO-UV ink delivers great results for indoor applications such as labels, packaging prototypes and POPs. For outdoor applications, EUV lasts up to two years when gloss is applied as a finishing process.

Unique Ink Configuration

VersaUV and TrueVIS boast a unique ink configuration that can include orange, red, white and gloss ink in addition to CMYK colours and primer. The high-opacity white ink is ideal for producing rich, dense colour graphics on clear, dark, opaque and even metallic substrates. The gloss ink adds high-gloss area highlighter (spot varnish), full flood gloss or matt finishing for added durability and special effects, such as three-dimensional textures and embossing by printing multiple gloss layers. Orange and red ink further increases colour gamut, adding vibrancy and impact to graphics. The combination of these features enables the production of exclusive prints that command premium prices, while considerably reducing production costs over conventional workflows.

Print onto virtually any substrate

Droplets of ECO-UV ink are cured by UV light immediately after they land on the surface of the media, leaving no time for the droplets to react or be absorbed by the media. This virtually eliminates any ink and media compatibility issues, meaning that EUV ink is able to adhere onto a wide variety of coated and uncoated media and 3D objects. Many stock media for equipment such as label printers and offset printers can be printed with EUV ink without any special treatment. The vast substrate compatibility of EUV ink means that users can print directly on three-dimensional objects such as awards, pens and giftware, acrylic plaques, golf balls, mobile phone covers and even laptop computers.

Colour Consistency

With ECO-UV inks, the absence of ink reaction and absorption means colours will be relatively consistent across different media types even without requiring profiles specific for the media.