Next-Gen

Direct-To-Film Printing

Performance. Productivity. Profits.

The best-in-class direct-to-film printer for bringing your boldest ideas to life on custom apparel and textiles.

NEW TY-300 Direct-to-Film Printer

Unleash unparalleled DTF performance and productivity with the TY-300. This powerful and reliable direct-to-film printer delivers stunning graphics and bold designs for heat transfer onto a wide range of materials, including cotton, polyester, denim, nylon, rayon, and more.

Transform custom apparel and textiles with dependable and sustainable technology that lets you produce vibrant colours, razor-sharp text, and fine details with pinpoint precision. With fast operations, superior ink efficiency, and cost-effective performance, your business can handle customisation jobs with unprecedented speed and efficiency.

Welcome to a new generation of DTF printing.

The TY-300 is part of Roland DG’s full DTF solution, with RIP software, DTF film and powder, and an optional shaker/heater unit for automated DTF transfer production.

Vibrant DTF Printing for All Types

of Custom Fabric Graphics

Benefits for your Business

Automate Your Workflow with the Roland DG Approved DTF Shaker Oven

The TY-300 printer seamlessly integrates with leading DTF powder shaker/heater units. To make it easy, we’ve tested and approved an optional bundle, for an automated system that puts on-demand customisation right at your fingertips.

This DTF shaker oven is specifically optimised for the TY-300, featuring a dedicated powder that delivers the highest image quality at the highest productivity. Additionally, the unit includes an attachment that connects the printer to this unit to minimise skew for more precise and efficient operation.

Powerful Performance.

Maximum Productivity.

The TY-300 delivers exceptional CMYK + White printing at 10.9 m2/h (Up to 45% faster* than other DTF printers on the market) and can even reach 17.48 m2/h in high-speed mode.

Plus, with superior ink efficiency, automated maintenance sequences, and innovative features like Perforated Sheet Cut, the TY-300 streamlines your workflow and reduces cost, delivering maximum productivity and value for your business.

*Compared to competitor models where tested

Print with Precision.

Down to the Smallest Details.

Bring any print to life with the TY-300’s advanced capabilities that enable you to print small text, intricate designs, photographs, and fine details with pinpoint precision.

Paired with the True Rich Color 3 setting, which ensures vivid colours, neutral greys, smooth gradations, and natural skin tones, and your prints are guaranteed to be stunning — down to the smallest details.

Uncompromising Safety and

Compliance with Exclusive DTF Inks

Designed exclusively for DTF printing, Roland DG’s newly developed S-PG2 inks optimise printer performance and are OEKO-TEX® Eco Passport certified, ensuring your custom apparel and textiles meet the highest global safety and sustainability standards.

Enjoy the peace of mind knowing that your inks are free from harmful substances, fully compliant with all international standards, including Europe’s REACH regulations, and contribute to a more sustainable production process.

Effortless Maintenance for Smooth Operations

Designed with consistent and high-quality printing in mind, the TY-300 comes equipped with automated maintenance features that keep your operations running smoothly. The print head is automatically cleaned based on your usage to prevent nozzle dropout, while the advanced white ink circulation system minimises ink clogging, guaranteeing stable white printing at all times.

Manual cleaning has also been made easier with our new head nozzle refresher tool that effectively cleans the print head surface. Plus, you can now replace key components, such as caps, wipers, wiper cleaners, and other items around the print head, without needing service personnel, making upkeep simple and hassle-free.

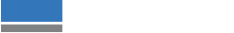

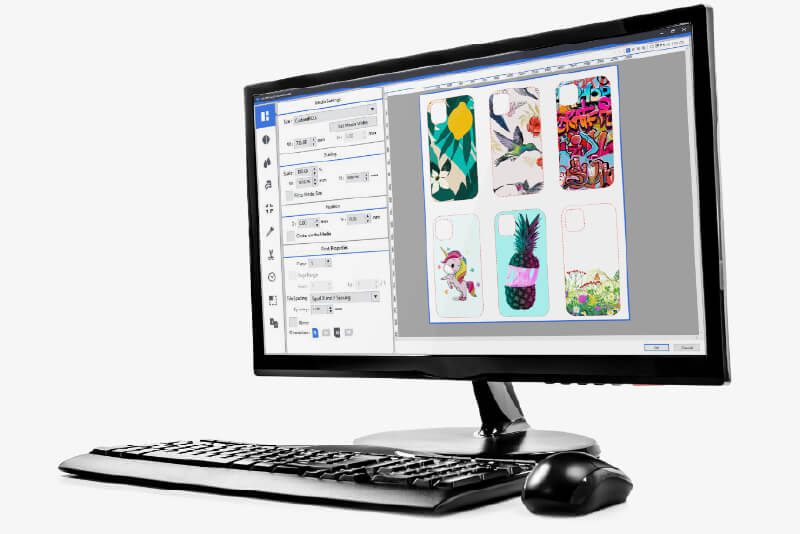

Powerful Software Included

The TY-300 solution is even more powerful when paired with Roland DG's advanced software solutions. Developed specifically for Roland DG, our fast and flexible software gives you all you need to produce your work, your way.

Protect Your Investment

Take your business forward with complete peace of mind thanks to Roland DG’s renowned post-sale service. Roland DG Care warranties cover you for much more than device maintenance.

- Factory-trained service engineers

- Quick installation and first-time set-up

- Expert advice and training.

Additional Information

Datasheet

Download Your TY-300 Datasheet

Get your digital guide to all the features, applications, benefits and specifications of the Direct-to-Film Printer.

Download DatasheetSpecifications

| TY-300 | ||

|---|---|---|

| Printing Method | Piezo ink-jet method | |

| Media | Width | 7.2 to 30 in (182 to 762 mm) |

| Thickness | Maximum 39.3 mil (1.0 mm) with liner for printing, Maximum 15.7 mil (0.4 mm) with liner and 8.6 mil (0.22 mm) without liner for cutting | |

| Roll outer diameter | Maximum 9.84 in (250 mm) | |

| Roll weight | 66.1 lb (30 kg) | |

| Core diameter | 3 in (76.2 mm) or 2 in (50.8 mm) | |

| Printing/cutting width (*1) | Maximum 28.9 in (736 mm) | |

| Ink | Type | S-PG2 INK 500 ml cartridge |

| Colours | Five colours (cyan, magenta, yellow, black, and white) | |

| Printing resolution | Maximum 1,200 dpi | |

| Cutting speed | 0.39 to 11.8 in/s (10 to 300 mm/s) | |

| Blade force (*2) | 30 to 500 gf | |

| Blade type | CAMM-1 series blade | |

| Blade offset | 0.0 to 59 mil (0.000 to 1.500 mm) | |

| Software resolution (cutting) | 0.98 mil/step (0.025 mm/step) | |

| Media heating system (*3) | Print heater set temperature: 86 to 113°F (30 to 45°C), Dryer set temperature: 86 to 122°F (30 to 50°C) | |

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | |

| Power-saving function | Automatic sleep feature | |

| Rated input | 100-120 / 220-240 Vac 50/60 Hz 6.4/3.0 A | |

| Power consumption | During operation | Approx. 840W |

| Sleep mode | Approx. 70W | |

| Acoustic noise level | During operation | 63 dB (A) or less |

| During standby | 58 dB (A) or less | |

| Dimensions (Width x Depth x Height) | 80 in x 29.5 in x 55.8 in (2,032 mm x 748 mm x 1,415 mm) | |

| Weight | 298 lb (135 kg) | |

| Environment | During operation (*4) | 68 to 82.4°F (20 to 28°C), Humidity: 40 to 60% RH (no condensation) |

| Not operating | 41 to 104°F (5 to 40°C), Humidity: 20 to 80% RH (no condensation) | |

| Included Items | Dedicated stand, Power cord, Media holders, Separating knife, Replacement blade, Cleaning liquid, Drain bottle, User's Manual, Software(VersaWorks, Roland DG Connect), etc. | |

| *1 | The length of printing or cutting is subject to the limitations of the program. |

| *2 |

|

| *3 |

Warm-up is required after power up. This may require 5 to 20 minutes, depending on the operating environment. Depending on the ambient temperature and media width, the preset temperature may fail to be reached. |

| *4 | Operating environment (Use in an operating environment within this range.) |

|

|