Roland digital printers:

a profitable choice for any screen printer

If you are an existing screen-printing business looking to accelerate production of short runs and one-off designs, or a new entrepreneur beginning to explore the world of bespoke and customised print, on-demand digital printing offers an exciting opportunity for your business. Digital printing technology is an affordable, creative and effective way to quickly bring colourful designs to life – on almost any material, in any size and any number.

Opportunities for screen printers

According to a FESPA Print Census report, sign and display will grow as a revenue stream for screen printers from 32% to 48%, followed by textiles, from 27% to 39%. Eco-solvent – the most popular and convenient solution for printing onto vinyl and PVC, as well as dozens of other substrates – will continue to grow, by 3%.

Direct-to garment (DTG) printing systems will play an important part in the revenue stream for screen print companies, both entry-level and mid-sized devices. Signs, posters, banners, decals, sports apparel, garments and fast fashion are the most widely produced applications in this market, followed by many more that are certainly worthwhile exploring, thanks to their high profit potential.

Quick and easy

from one to hundreds

Digital printing offers a range of benefits that can help your screen printing business make healthy profits – while you remain creative, customer-focused and in control.

Digital printing is a perfect complement to your screen printing and pad printing applications. It satisfies on-demand requests for short-run production on almost any material, combined with steadier long-run graphic output delivered by screen printing. In this way, you can fulfil a whole range of customer demands while retaining the creative potential to offer brand-new graphic applications.

Fast, accurate

and durable printing

One of the most exciting features of digital printing is its exceptional responsiveness, with no need for film and screen preparation. The set-up is immediate: switch on your digital printer when you arrive in the studio, set the artwork in your graphic software and start printing. It's that quick and straightforward to print full-colour images without multiple layers. Digital printers offer different print speeds depending on the required output quality, giving you a number of options to achieve fast production and accurate colour reproduction.

Opportunities and Applications

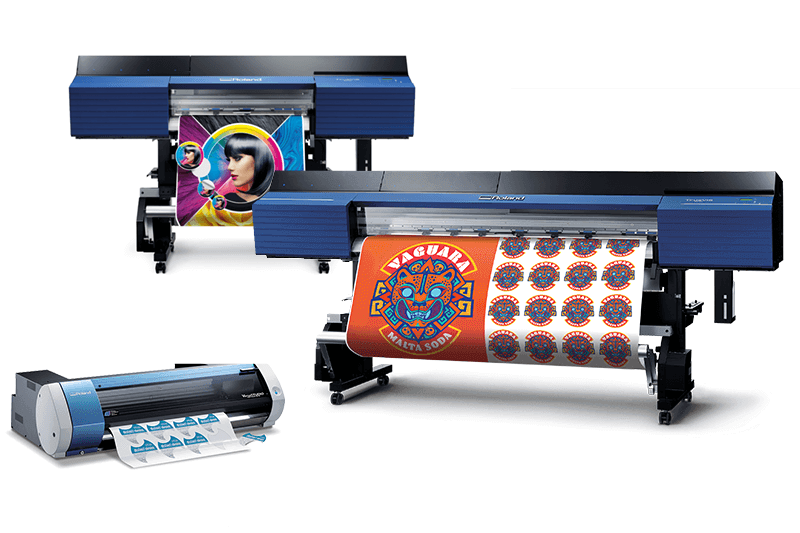

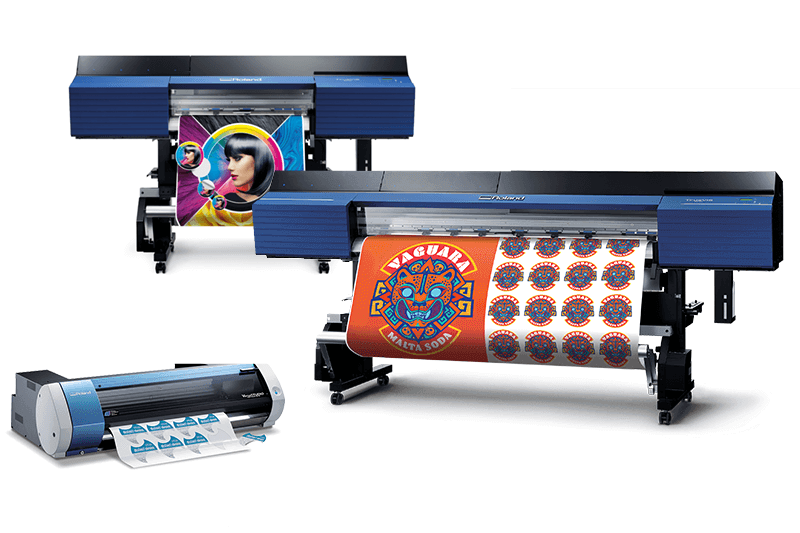

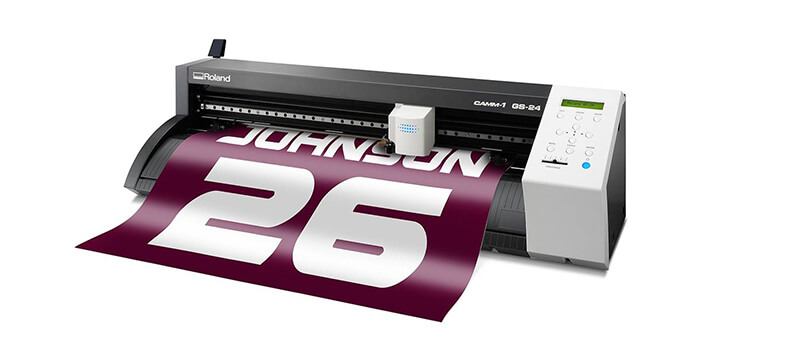

As you've seen, digital printing technology can boost a screen printing workflow by adding a quick-print option, expanding a colour gamut and increasing material compatibility. Some digital printers are very compact and affordable, allowing businesses to invest in the latest technology that won't break the bank, while other systems are larger production models, or also feature a contour-cutting function that can take the work out of manual finishing processes.

As a screen printer, you undoubtedly get a variety of requests from your customers. Choosing new equipment that offers the right flexibility to produce many different kinds of applications, or pairing two different technologies, will add more power to your printing portfolio. Roland systems offer excellent application versatility, so you can bring your creative ideas to life or respond to your customers' requirements on-demand. Let's dive into the most exciting applications you can offer using Roland digital printers.

Unique customisation

and short runs

The possibility to offer truly one-off pieces and very short runs: another aspect that makes digital print a perfect partner for screen printers. Using digital printing methods, it's as cheap and easy to print one design as it is to print hundreds, so you can offer your customers genuinely unique products while being sure your investment is paying off.

The software provided with digital devices allows using variable data. This means you can personalise every single product with a different graphic or piece of text.

You can also group different kinds of graphics together through the software's nesting function, maximising material use and reducing waste.

Set-up costs

For digital printing, set-up costs are low – essentially just the cost of material and ink – and you can start printing right away, as soon as the file is ready. Furthermore, once you receive the file from the customer you can move from one application to another, often on the same machine. If you have a combined print and cut device, you can offer your customer a poster, a series of stickers, a T-shirt, a window graphic, a car decal and more, simply by changing the material on your digital device.

Compact or production-sized

Digital printers, whether they use eco-solvent, UV or textile printing technology, are built to fit into small studios as well as larger production environments. When you consider a digital printer for your screen printing company, you usually have a choice of different sizes to help you select the perfect system for your workspace and production needs. For textile, UV and eco-solvent printing there are several options in terms of size, so it's easy to add a small-footprint system into your existing workflow and upgrade to a larger production printer when the right time comes. Some printer models are genuinely desktop-sized, which has enabled lots of entrepreneurs to start their businesses from a kitchen table, and companies of any size to add small printed work to their services.

Ready to work,

right out of the box

It's essential to be able to integrate new technology into your daily working process quickly and easily. When choosing a piece of new equipment, you should have the reassurance that it will be easy to install, fit into your workflow and have a smooth learning curve. One of the exciting aspects of digital printing, whatever the technology, is that it can fit easily into your daily routine and you and your staff can be ready to print after just few hours of training. You don't have to wait to be productive.

The right technology for you

The choice of technology is one of the fascinating aspects of digital printing – and once you have adopted one you'll want to run many different systems side by side, to expand your services and approach exciting new markets. There are several types of digital printing technologies that can be the perfect accompaniment to screen printing or help a new business get off the ground. All are easy to use, are clean and safe, and produce amazingly accurate results in terms of image clarity and colour reproduction.

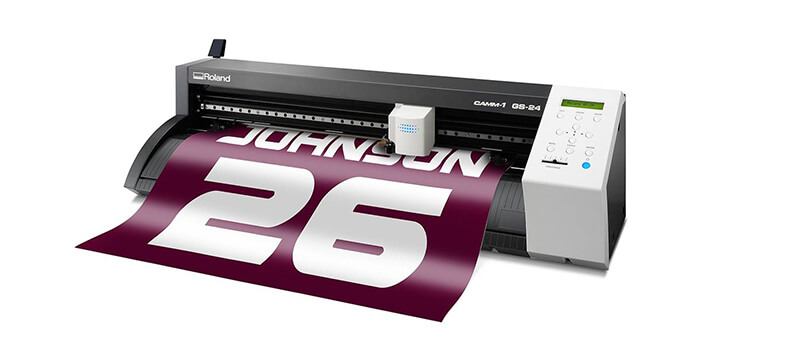

Eco-solvent printing

Today, eco-solvent is the most popular choice for printing on vinyl. It's incredibly versatile, so you can quickly move from stickers and signs to posters, art canvases and domed stickers, to window graphics, sportswear and workwear. There's no doubt that digital inkjet printing offers the widest choice of colours for crisp text, colour-matched images and punchy photographs. Some Roland devices combine print and cut functions, giving you the possibility to cut vinyl for different applications like road signs or floor graphics with no extra equipment.

Some eco-solvent print and cut devices, like the Roland TrueVIS series, offer orange, white and metallic inks. This means you can reproduce an expanded colour gamut, add special effects to a wide range of media thanks to a pre-stocked library, or achieve a screen-printed effect.

UV printing

UV is one of the most rapidly developing technologies in this sector and a must-have for any screen printer or pad printer. Available in different sizes and production capacities, UV printing is perfect for a huge range of output, from personalised products and giveaway items, to electronic devices and packaging prototypes, and many more.

There are different Roland UV devices for different targets. Benchtop VersaUV devices offer incredible flexibility in terms of size and production speed, making them ideal for the customisation of small items. Others, like the IU-1000F flatbed, deliver exceptional productivity and are the perfect solution for printing on boards and objects at fast speeds.

UV also couples perfectly with eco-solvent print, especially as they share the same RIP software to minimise the learning curve. The colour reproduction is very high quality and detailed, and many devices, such as some from Roland VersaUV series, can run white ink and varnish to achieve 3D matte and glossy effects on your work.

Heat transfer printing

Heat transfer printing – also known as digital transfer or thermal transfer printing – is a popular way to decorate textile products like T-shirts, caps and tote bags. Your designs are printed onto transfer paper, then heat and pressure are applied to transfer the ink onto the fabric. Roland offers a range of digital printer/cutter systems to make this process clean and smooth.

Again, you can couple such devices with your screen printing systems. Today, manufacturers offer dozens of different materials that are compatible with print and cut eco-solvent machines – flock, 3D, embossed, stretchable and many more. You can quickly expand your application portfolio just by changing the material in your device.

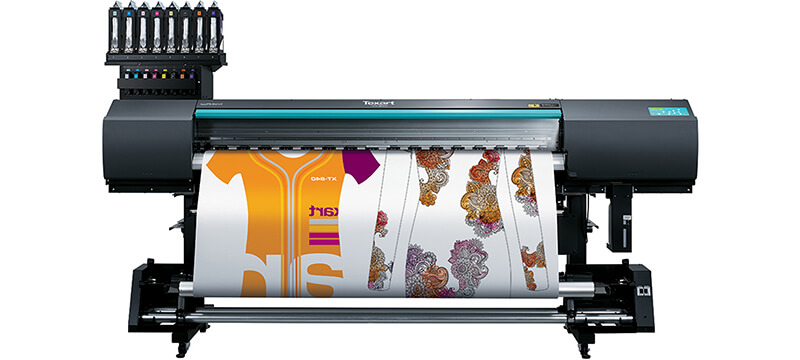

Dye-sublimation printing

Dye-sublimation printers are ideal for adding your artwork to durable fabrics, even in the brightest and deepest colours. These systems use the heat-transfer method to transfer, through a calender, crisp and colourful decoration to textiles like apparel and soft signage. They can also be used to customise rigid products like or aluminium plates or motorbike helmets. Another exciting application is sportswear. You can transfer your prints onto stretchable and technical textiles to produce team uniforms and sports kit, on demand.

The Roland Texart range has been designed specifically for fast and effective dye-sublimation printing and includes systems for both direct (directly to textile) and indirect printing (prints on paper that are transferred onto fabrics through a calender).

Direct-to-garment printing

Software

Go further into the fast-moving world of bespoke and customised print with Roland software, developed to maximise the potential of our digital printing solutions.

PersBiz

The cloud-based Roland PersBiz solution makes it easy to set up a webshop and start selling. It enables you to manage your product range, the printing process, the look and feel of your shop, and payment, shipping and delivery options all in one place.

Choose from the two packages – the general purpose PersBiz eCommerce and the commercial-focused PersBiz Business eCommerce – to meet your needs.

Get a consultation

If you are a screeprinter (copy shop etc.) looking for more information about how Roland can help to expand your business, asking to our expert filling the form below.